■ AEAUTO presented the latest electric drive technology to help the commercial vehicle industry move towards a more sustainable future.

■ Meet the needs of electrification and autonomous driving; Meet the high torque requirements of commercial vehicle steering

■ Advanced new electric power steering pumb systems for trucks, coaches and city buses provide a solid foundation for electrification and autonomous driving.

AEAUTO new Electric Power Steering system lays the foundation for the electrification transition in the commercial vehicle industry. Suitable for a wide range of medium and heavy duty trucks, coaches and city buses, the EPS system is also one of the key elements in the realisation of the next generation of Advanced Driver Assistance Systems (ADAS), which will drive the vision of autonomous driving in the commercial vehicle industry.

The use of an integrated electric motor instead of a hydraulic pump removes the electric power steering system from the vehicle driveline an+d eliminates the need for hydraulic fluid assistance. Seamlessly adapted to electric vehicle architectures, the system optimises the driving experience through quiet and smooth electric handling while achieving zero local emissions for pure electric and fuel cell vehicles.The EPS system is available in all powertrain concepts to seamlessly match the architectural requirements of electric vehicles. The modular EPS system, adapted to 24V battery packs, supports power outputs of up to 8,000Nm and has a scalable design to meet the requirements of diverse packages.AEAUTO EPS system is currently available for steer-by-wire, and, thanks to its highly reliable and redundant architecture, as an active electric power steering system, the EPS can be integrated with ADAS to enable safety functions such as Continuous Lane Keeping.

AEAUTO Core Technology of EPS

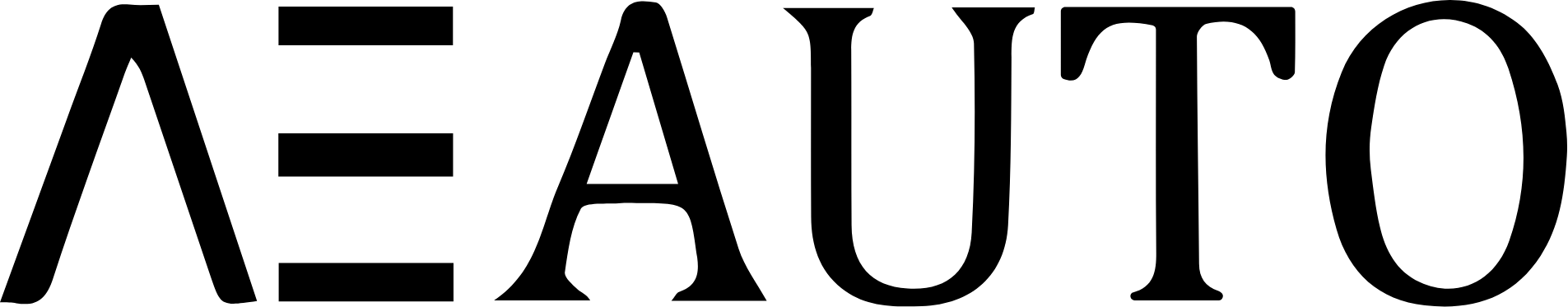

■Heavy commercial vehicles with heavy loads require a steering output torque of 8000Nm, which is achieved through double-winding motor and high-precision variable large transmission ratio deceleration mechanism.

AEAUTO EPS achieves high torque output through dual-winding motors and high-precision variable ratio gearboxes for heavy commercial vehicles with heavy loads and a required steering output torque of 8,000Nm.

24V High power motor: double winding low slot torque, low moment of inertia permanent magnet synchronous motor, output torque of 8000Nm after deceleration.

Patented deceleration mechanism: through high-precision ball screw, planetary wheel and planar secondary enveloping torus worm to achieve a variable transmission ratio of 15~23.

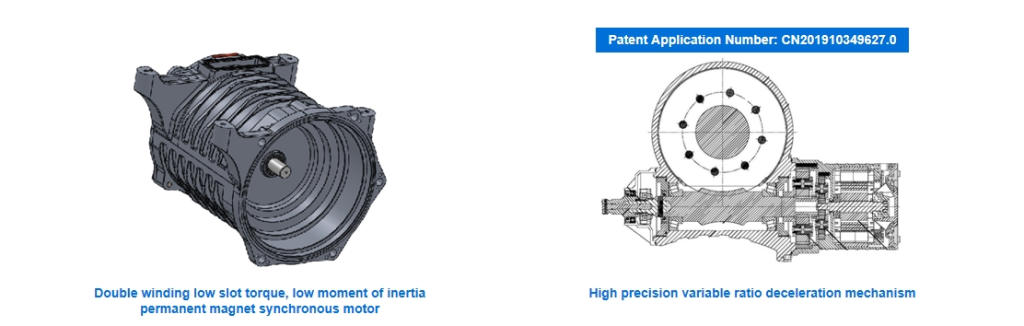

■Double winding motor for heavy commercial vehicles + Double MCU+ Double control chip based on functional safety redundant architecture, leading in China.

The steering system is a functional safety component, and the high reliability and safety of electric steering are just necessary.

Highly reliable redundancy design: dual power source + double winding + double MCU+ double control chip based on functional safety redundancy design to ensure high reliability and safety.

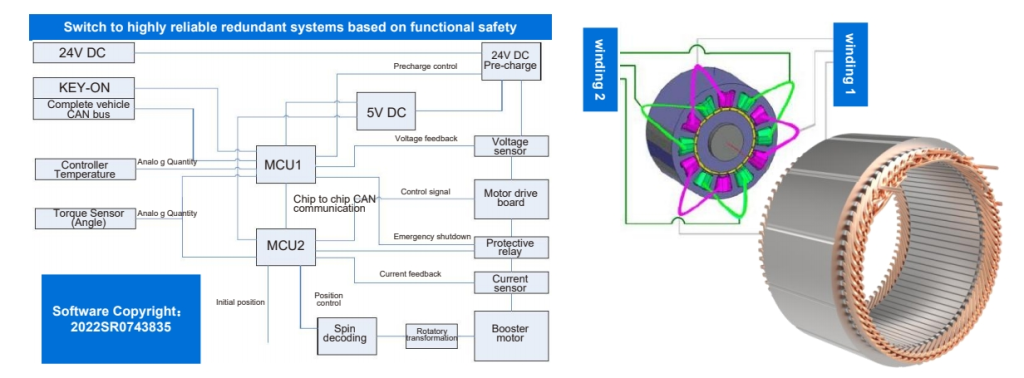

■Based on the dynamic tracking and feedback control strategy in the loop of the booster value, the response time of angle control is ≤50ms, leading at home and abroad.

The response time of the steering system is very critical for heavy commercial vehicles in high-speed scenarios. With the same steering wheel angle control precision, the shorter the response time, the higher the maximum speed allowed to be reached.

Adopting low rotational inertia permanent magnet synchronous motor with high mechanical sensibility and matching precision, the steering system makes judgment on the control mode through different sensor signals, uses the control algorithm to track the target parameters accurately, and controls the motor to output the ideal assisting torque according to the optimized assisting curve to realize the fast response of EPS assisting.

Advantages Of Electric Power Steering Over Electric Hydraulic Steering

■System Efficiency Increased by 30%

No hydraulic link energy consumption loss, high efficiency;

Electric + wire control to meet the needs of heavy commercial vehicles such as electric vehicles and autonomous heavy trucks.

■35% Reduction in System Weight

Light weight and small size: Compared with traditional hydraulic or electro-hydraulic steering, electric drive-by-wire steering eliminates 5 components such as hydraulic pump and hydraulic steering device, and is completely driven by motor to achieve steering.

■Total System Cost Reduced by 20%

After the cancellation of five components such as hydraulic pump and hydraulic electric power steering gear, the overall cost of parts was greatly reduced after the allocation of R&D investment and mold costs.

AEAUTO EPS has been used in Europe (Norway, Finland) and the Middle East to help achieve low energy consumption and zero emissions in transport, providing an indispensable support for the creation of environmentally friendly societies and the promotion of sustainable development of various industries, as well as providing valuable examples for the development of related fields in other regions of the world.