In the current era of electrification and autonomous driving of heavy-duty commercial vehicles, the innovation of commercial vehicle steering systems is of utmost importance. AEAUTO shines in the field of commercial vehicle power steering electric, particularly in the area of electric steering-by-wire, with its outstanding technology and products.

The development of autonomous driving functions for commercial vehicles is currently facing technical challenges. Foreign products are unavailable in China, and the domestic commercial vehicle market has a growing demand for localization. Traditional and electric hydraulic steering have taken on the challenge and successfully developed the first generation of commercial vehicle electric wire-controlled steering systems, providing a new solution to the industry.

Advantages of AEAUTO‘s Power Steering Electric System

1. Increased System Efficiency by 30%

There is no energy loss in the hydraulic link. The design combines electricity and wire control, perfectly catering to the needs of heavy-duty commercial vehicles like electric vehicles and self-driving heavy trucks.

2. Reduced System Weight by 35%

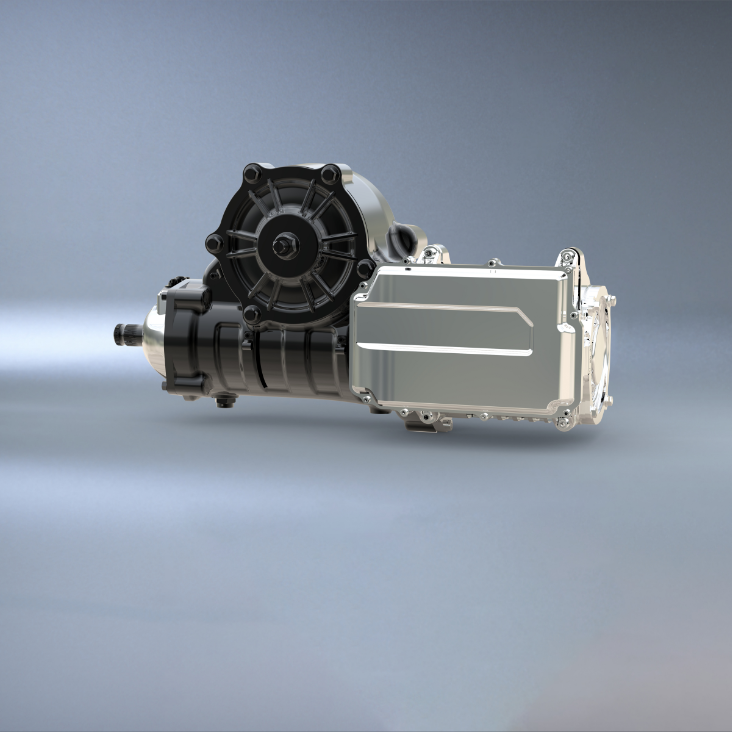

Compared to traditional hydraulic or electric hydraulic steering, this system eliminates five components such as the hydraulic pump and hydraulic steering gear. Steering is entirely driven by an electric motor, which is lightweight and small in size.

3. Reduced Total System Cost by 20%

After removing multiple components and amortizing the R&D investment and mold costs, the overall cost of parts is significantly reduced.

Core Technology Advantages of AEAUTO’s Power Steering Electric System

1. 8000Nm High Torque Output

Through a dual-winding motor, high-precision ball screw, and flat secondary enveloping toroidal worm reduction mechanism, along with a 24V high power density motor and patented reduction mechanism, the required 8000Nm high torque output for heavy-duty commercial vehicles is achieved.

2. High-Reliability Redundant Design

Utilizing a functional safety-based redundant architecture with dual-winding motors, dual MCUs, and dual control chips for heavy-duty commercial vehicles ensures the high reliability and safety of the steering system, meeting the urgent needs of the electric steering system as a functional safety component.

3. Angle Control Response Time Not Exceeding 50ms

Based on the in-loop dynamic tracking and feedback control strategy of the power assist value, it adopts a low-inertia permanent magnet synchronous motor, determines the control mode through different sensor signals, and uses the control algorithm to accurately track the target parameters to achieve rapid response of EPS power assist, reaching the international leading level.

Compared with foreign competitors, AEAUTO has better performance in terms of system voltage and angle control response time. Although 48V voltage is designed to output more power, it is not a common standard. AEAUTO achieves high power output with its unique reduction mechanism without compromising matching and compatibility. Additionally, the company’s control strategy and algorithm are excellent, resulting in a better angle control response time.

AEAUTO’s Power Steering Electric Enables Heavy-Duty Trucks to be More Electrified and Autonomous

Our products have undergone a series of rigorous tests, including performance tests, bench tests, and durability tests, and obtained the EU CE certification in June 2021. In terms of customer cases, the electric buses of Karsan in Europe and the products of Otokar, a leading Turkish bus company, both use AEAUTO’s electric steer-by-wire system and are sold to many European countries and the United States.

Furthermore, AEAUTO has also established a heavy-duty commercial vehicle electric steering R&D test platform, which encompasses software-in-the-loop simulation, testing, calibration, reliability, and durability test benches and has passed the assessment of the Nanjing Engineering Technology Center.