What Does EPS Do in a Truck?

In the trucking industry, the steering system is of utmost importance. It directly affects vehicle safety, handling ease, and the smoothness of overall operations. The emergence of Electric Power Steering, abbreviated as EPS is gradually revolutionizing the traditional steering methods of trucks. According to data, in some advanced commercial truck markets, the installation rate of EPS is increasing year by year, with an annual growth rate of around 15%, which clearly indicates its significant utility in the truck sector. EPS, with its unique technological features, enables trucks to have more precise, effortless, and intelligent steering, ensuring stable driving regardless of road conditions. It is truly a major contributor to the advancement of truck technology.

How Does EPS Make a Truck Steer?

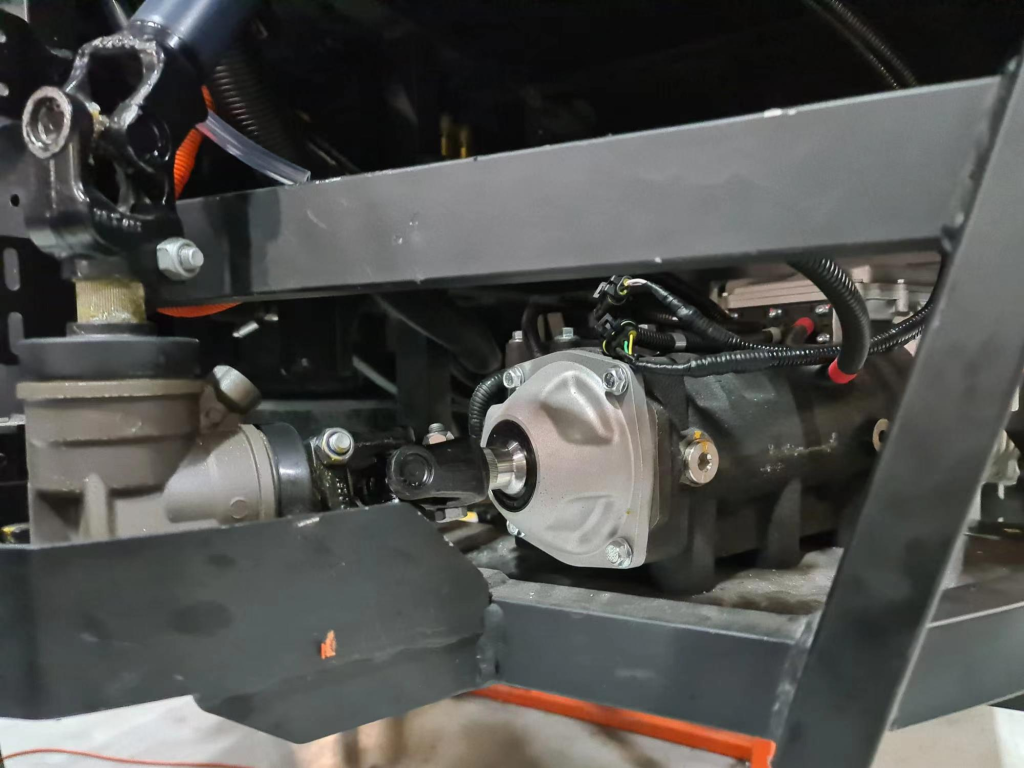

The electric power steering used in trucks mainly consists of several key components, such as a torque sensor, an Electronic Control Unit (ECU), a high-power electric motor, and a reduction mechanism. As soon as the driver turns the steering wheel, the torque sensor immediately detects the magnitude and direction of the torque applied on the wheel and promptly transmits this information to the ECU.

The ECU then combines the received torque data with other information such as the truck’s current speed, steering angle, and load weight, and calculates, through a complex algorithm, the required assist torque for the electric motor. For example, when the truck is empty and moving at a low speed (less than 30 kilometers per hour), EPS can provide approximately 80% of the assist torque, making it extremely easy for the driver to turn the steering wheel.

This is especially convenient when reversing or turning in a warehouse or loading/unloading area. When the truck is fully loaded and traveling at high speed (above 80 kilometers per hour), the assist torque is reduced to 20% – 30%, ensuring a stable and safe steering feel. Subsequently, the electric motor generates the corresponding assist torque according to the ECU’s instructions, which is amplified by the reduction mechanism and helps the driver to turn the truck.

This method of adjusting the assist torque in real-time according to the actual driving conditions enables EPS to perfectly match the steering requirements of trucks under different loads and speeds, providing a comfortable driving experience and highly accurate steering.

What Benefits Does EPS Bring to Trucks?

- Easier and Safer Driving

Truck drivers often have to endure long hours of driving and face various complex road situations. EPS can adjust the steering assist precisely based on the vehicle speed and load, significantly reducing the driver’s fatigue. When driving in urban areas or during reversing and parking, the light steering wheel allows the driver to control it with minimal effort. When traveling long distances on highways, the stable steering wheel enables the driver to maintain a straight driving path more effectively, reducing the risk of accidents. A survey shows that truck drivers using EPS experience approximately 30% less fatigue after 8 hours of driving compared to those using traditional steering systems, which is highly beneficial for both safety and work efficiency. - Enhanced Vehicle Stability and Reduced Accident Risks

When trucks are traveling at high speeds or carrying heavy loads, vehicle stability is of critical importance. EPS can intelligently adjust the steering assist, providing an appropriate resistance to the steering wheel at high speeds to prevent the vehicle from losing control due to excessive sensitivity. In the event of sudden situations such as strong crosswinds, uneven road surfaces, or emergency maneuvers, EPS can work in conjunction with the vehicle’s Electronic Stability Program (ESP) to rapidly adjust the steering force and help the driver maintain the vehicle’s stable driving posture. For instance, in the presence of strong crosswinds (wind speed exceeding level 8), EPS can adjust the steering force within 0.2 seconds, reducing the vehicle’s lateral deviation by about 40%, thereby enhancing safety during driving in adverse conditions. - Fuel Efficiency and Improved Load Capacity Utilization

Trucks carry varying loads, and traditional steering systems often perform inconsistently under different load conditions. EPS, on the other hand, can automatically adjust the assist torque according to the load, ensuring proper steering feel whether the truck is empty, half-loaded, or fully loaded, and facilitating smooth vehicle operation. Moreover, EPS only consumes electrical energy during steering, unlike traditional hydraulic steering systems where the hydraulic pump continuously operates and consumes engine power. Experimental data indicates that trucks equipped with EPS can achieve a 4% – 6% improvement in fuel economy during long-distance transportation, which is highly valuable for reducing truck operating costs and maximizing load capacity utilization. - Convenient for System Upgrades and Enhanced Intelligence

Modern trucks are evolving towards intelligence and connectivity, and EPS, as a highly intelligent system, can seamlessly integrate with other onboard systems such as autonomous driving assistance systems and vehicle networking systems. Its compact structure also allows for more rational layout of the truck’s engine compartment, facilitating the installation of other advanced electronic devices or emission treatment systems. In the development of autonomous trucks, EPS can accurately execute steering instructions from the autonomous driving system, laying a solid foundation for future intelligent logistics transportation.

How Will EPS Develop in the Truck Field?

-

Increased Power and Torque Output Capability

With the continuous increase in truck load capacity and the growing demand for transportation efficiency, EPS will need to have higher power and torque output capabilities in the future. The development of new high-power electric motors and efficient transmission mechanisms is essential to meet the stringent requirements of heavy-duty trucks for steering assist during full-load start-up, climbing, and high-speed driving. It is estimated that within the next five years, the maximum power output of EPS systems will increase by 30% – 50%, and the maximum torque output capacity will improve by 20% – 30%, ensuring that large trucks can achieve stable and accurate steering under all kinds of complex road conditions. -

Greater Intelligence and Autonomy

In the context of rapid development in intelligent transportation and autonomous driving technologies, truck EPS will need to become more intelligent and autonomous. By deeply integrating with more sensors (such as lidar, cameras, high-precision maps) and onboard computer systems, EPS can possess more advanced autonomous driving assistance functions, such as automatic lane keeping, lane changing, and parking. EPS will also have self-diagnostic and predictive maintenance capabilities, enabling it to monitor its own operating status in real-time, predict potential faults in advance, and transmit fault information to maintenance service centers via remote communication, thereby enhancing the reliability and availability of truck operations. -

Enhanced Reliability and Durability

Given the harsh working environment, long mileage, and heavy loads of trucks, the reliability and durability of EPS will be a key focus in future research and development. The adoption of more advanced materials and manufacturing processes, optimization of the heat dissipation design, and improvement of the fatigue resistance and corrosion resistance of electric motors, electronic components, and mechanical parts will ensure that EPS can operate stably for long periods in high-temperature, high-humidity, dusty, and complex road conditions. For example, the development of new motor winding materials with high temperature resistance and excellent insulation properties can extend the service life of electric motors by 25% – 35%. Improving the lubrication and Sealing technology of the reduction mechanism can reduce wear and enhance its durability, significantly increasing the overall fault-free operation mileage of EPS systems and meeting the demands of trucks for long-term and high-intensity operations.

The application of Electric Power Steering, which we’ve been discussing in the truck field has completely transformed the truck’s steering and operation modes. It excels in providing more precise steering, enhanced vehicle stability, improved fuel efficiency, and increased intelligence, representing the main direction of modern truck technology development. With continuous technological innovation and progress, EPS will undoubtedly achieve greater breakthroughs in power, intelligence, and reliability, bringing more efficient, safe, and intelligent transportation solutions to the truck industry and promoting the vigorous development of the global logistics and transportation industry.